Monitoring the Unseen, Managing the Risk

Geonamics specializes in comprehensive instrumentation and monitoring solutions for civil and geotechnical engineering applications. From tracking deformation and settlement in retaining structures and slopes to monitoring underground water fluctuations and excess pore water pressure, we deliver accurate and real-time engineering insights. Our structural health monitoring services encompass temperature control during mass concrete casting, bridge deformation analysis, crack monitoring, and dilapidation surveys—providing precise data to safeguard your projects.

More than just conventional monitoring systems, our foundation lies in innovation. We incorporate exclusive advanced sensors and ongoing R&D to tailor bespoke monitoring solutions that help our clients make data-informed decisions throughout the project lifecycle.

Special Exclusive Sensors

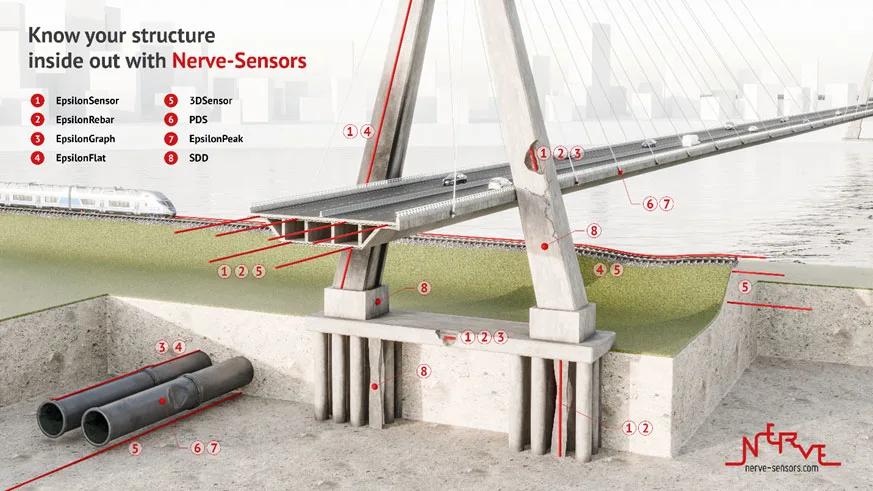

Advanced sensor technologies provide real-time, high-precision monitoring essential for assessing geotechnical and structural performance. These sensors enhance accuracy, facilitate early warning systems, and optimize maintenance strategies. At Geonamics, we deploy cutting-edge systems such as Distributed Fibre Optic Sensing (DFOS) and Shape Accel Array (SAA) to track ground and structural movements. These technologies ensure safety, performance, and cost-efficiency over a structure’s lifespan.

Distributed Fibre Optic Sensing (DFOS) Technology

Distributed Fibre Optic Sensing (DFOS) is a transformative tool in structural health monitoring. It continuously measures strain, temperature, and vibration along the entire length of an optical fibre, covering distances up to 10 km. When embedded in or attached to a structure, the fibre acts as a continuous sensor, detecting subtle physical changes in real time. This makes DFOS highly suitable for large-scale infrastructure such as tunnels, bridges, embankments, and pipelines.

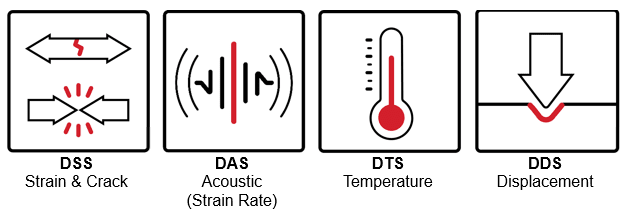

Geonamics integrates the world’s first composite and monolithic DFOS sensors into client projects. Depending on the interrogator type and installation method, we configure DFOS systems to measure:

(a) DSS -> Distributed strain sensing,

(b) DTS -> Distributed temperature sensing,

(c) DSS -> Distributed displacement sensing (DDS),

(d) DAS -> Distributed acoustic sensing

These capabilities create a “nerve system” within infrastructure, offering unmatched spatial resolution for comprehensive condition monitoring.

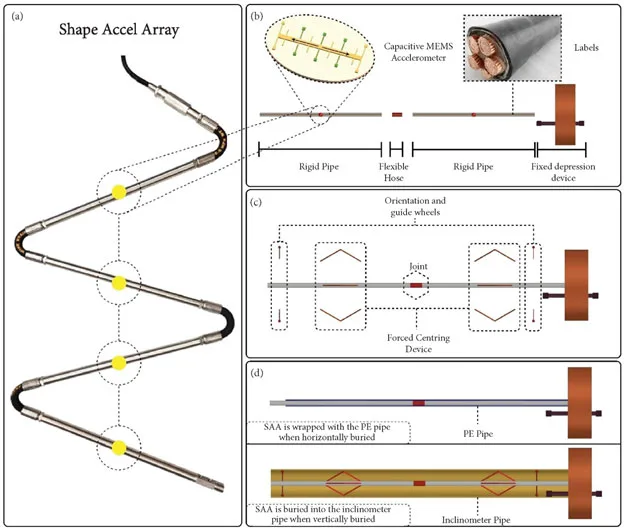

Measurand’s Shape Accel Array (SAA)

The Shape Accel Array (SAA) employs advanced microelectromechanical systems (MEMS) to measure 3D deformation continuously and precisely. Its core consists of serially connected MEMS-based accelerometers that calculate positional changes using tilt and motion data. Installed vertically in boreholes or embedded in structural elements, the SAA captures displacement and deformation trends across various depths or lengths. Geonamics has a proven track record using SAA systems in monitoring ground movements, retaining walls, and bridges. Their low-power, durable design allows long-term, real-time monitoring with minimal maintenance. These characteristics make SAA an ideal choice for early detection of movement or failure in both temporary and permanent civil structures.

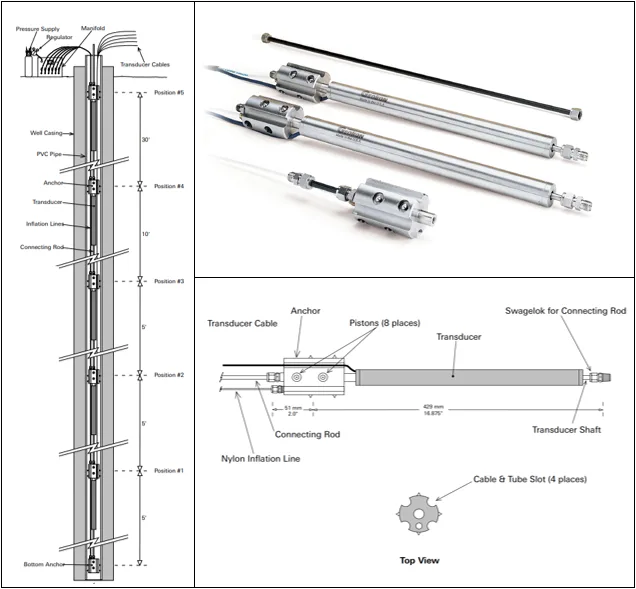

Modified Multiple Point Retrievable Extensometer (Geokon Model A-9)

Originally developed to measure deformation in rock or concrete via boreholes, the Geokon Model A-9 extensometer has been adopted and enhanced by Geonamics for a wider range of applications. The system uses pneumatically actuated anchors and spring-loaded transducers connected by a central rod. Once installed at various depths, each anchor point tracks differential movement with high sensitivity.

Geonamics has introduced modifications to the anchoring system to allow more flexible installations, including confined or irregular boreholes. Over the years, our team has successfully deployed the A-9 in pile load tests, plate jacking tests, and foundation monitoring. This extensometer is especially valuable for detecting differential settlement, compression, and structural elongation with depth.

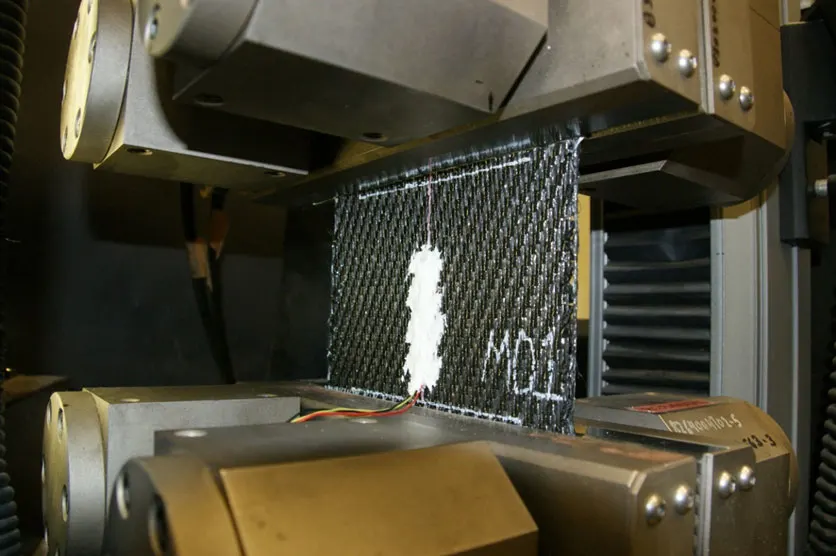

Unique Strain Gauges on Geosynthetics Materials

Geonamics has pioneered the integration of custom strain gauges into geosynthetic materials such as geotextiles, geogrids, and geotextile tubes. These gauges monitor strain under both static and dynamic conditions, capturing performance data from installation through to long-term service. The system is highly effective in applications such as reinforced soil walls, embankments, and disposal of geotextile tubes / container onto the seabed. By calibrating the strain readings in our accredited laboratory, actual mobilized forces in the geosynthetics can be deduced with precision. This innovation provides engineers with a powerful tool for verifying design assumptions and optimizing geosynthetic-reinforced systems in the field.

Conventional Sensors

Strain Measurement - VW & Resistance Strain Gauges

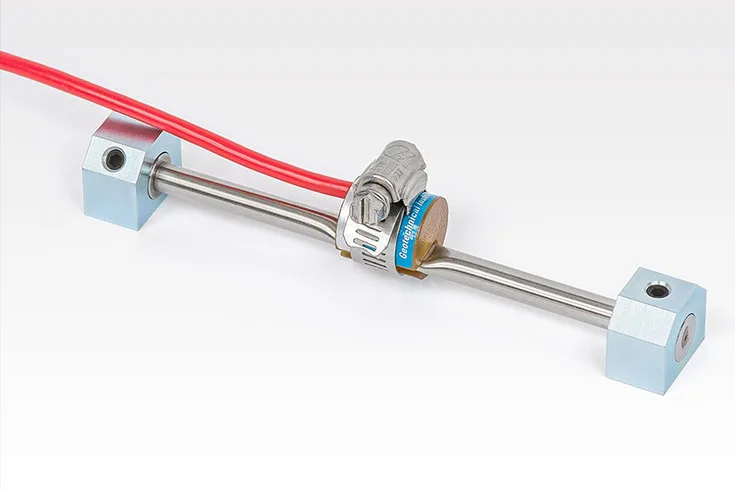

Strain gauges are essential tools for evaluating structural stress and deformation. Vibrating Wire (VW) strain gauges operate based on frequency changes in a tensioned wire as it elongates or contracts under strain. This method is highly stable over long durations and is immune to electrical noise, making it ideal for long-term geotechnical and structural applications.

Resistance strain gauges, in contrast, rely on changes in electrical resistance in a metallic foil or wire when deformed. These are more sensitive to microstrain and are suitable for short-term or laboratory-based applications. Geonamics uses both types across bridges, piles, tunnels, and retaining walls to monitor strain behavior, validate design assumptions, and detect signs of structural distress.

Displacement Measurements - LVDT, settlement marker, survey method via total station & dumpy level

Displacement monitoring involves quantifying movement in structures and ground surfaces over time. Linear Variable Differential Transformers (LVDTs) are electromechanical devices that convert linear motion into an electrical signal, offering high precision for lab tests or controlled site applications.

Settlement markers are simple yet effective tools installed at the ground surface or within embankments to track vertical settlement using level surveys. For wider-scale monitoring, total station surveys provide precise, repeatable displacement readings of targets installed on structures or soil surfaces. These methods allow Geonamics to monitor deformation trends and evaluate construction impacts, particularly in sensitive urban or infrastructure settings.

Inclination – Inclinometer

Inclinometers are used to measure subsurface lateral movement, typically within slopes, embankments, or retaining walls. A casing is installed in a borehole, and a probe is lowered along its length to measure tilt at defined intervals. Repeated measurements over time reveal horizontal displacement profiles, helping identify shear zones or potential failure planes.

Geonamics employs both manual and automated digital inclinometers, allowing for flexible monitoring frequencies depending on project needs. These systems are crucial in slope stability assessments, excavation support monitoring, and embankment behavior tracking.

Building Tilting Measurement - Tiltmeter

Tiltmeters measure the angular movement of structures to detect tilting, which may indicate foundation settlement or lateral soil movement. These compact sensors are fixed to the structure and monitor tilt in one or two axes, with high sensitivity to minute angular changes.

Geonamics uses both uniaxial and biaxial tiltmeters, including digital variants with data loggers for real-time monitoring. Tiltmeter data is vital for assessing building performance adjacent to deep excavations, tunneling works, or during long-term settlement of reclaimed land and fill areas.

Water Level & Pore-water Pressure Monitoring (Piezometer)

Monitoring groundwater behavior is critical for understanding soil stability and hydrogeological conditions. Water levels are typically recorded using standpipe piezometers or pressure transducers. For deeper insights, Vibrating Wire Piezometers (VWPs) measure pore-water pressure directly, providing real-time readings and high long-term stability. These sensors are widely used by Geonamics in slope stability projects and excavation dewatering assessments. Tracking water pressure variations helps engineers anticipate failure risks or design drainage systems more effectively.

Noise & Vibration Monitoring

Construction activities often produce noise and vibration that can affect nearby structures and communities. Noise levels are monitored using sound level meters, while vibration is tracked using geophones or accelerometers, typically presented as peak particle velocity (PPV).

Geonamics provides real-time noise and vibration monitoring systems with alert thresholds, data logging, and compliance reporting. These services support regulatory compliance and safeguard sensitive structures and public welfare near active construction zones.

Dilapidation Survey

A dilapidation survey involves a detailed inspection of nearby buildings and infrastructure before, during, and after construction activities. This visual record documents pre-existing defects such as cracks, misalignments, or material deterioration. It serves as a baseline to identify any construction-induced damage.

Geonamics offers comprehensive dilapidation survey services with photographic documentation, drawings, and condition reports. This helps mitigate disputes, provides legal protection, and ensures accountability for developers and contractors during construction adjacent to existing properties.

Geotechnical Case References

Several noteworthy geotechnical projects carried out by Geonamics demonstrate the effectiveness and innovation of our instrumentation and monitoring capabilities. These case references highlight the use of specialized sensors that provide insights into soil-structure interaction, load transfer behavior, deformation patterns, and pile performance in both static and dynamic conditions. For more details or technical inquiries regarding any of the case studies below, kindly contact us directly.

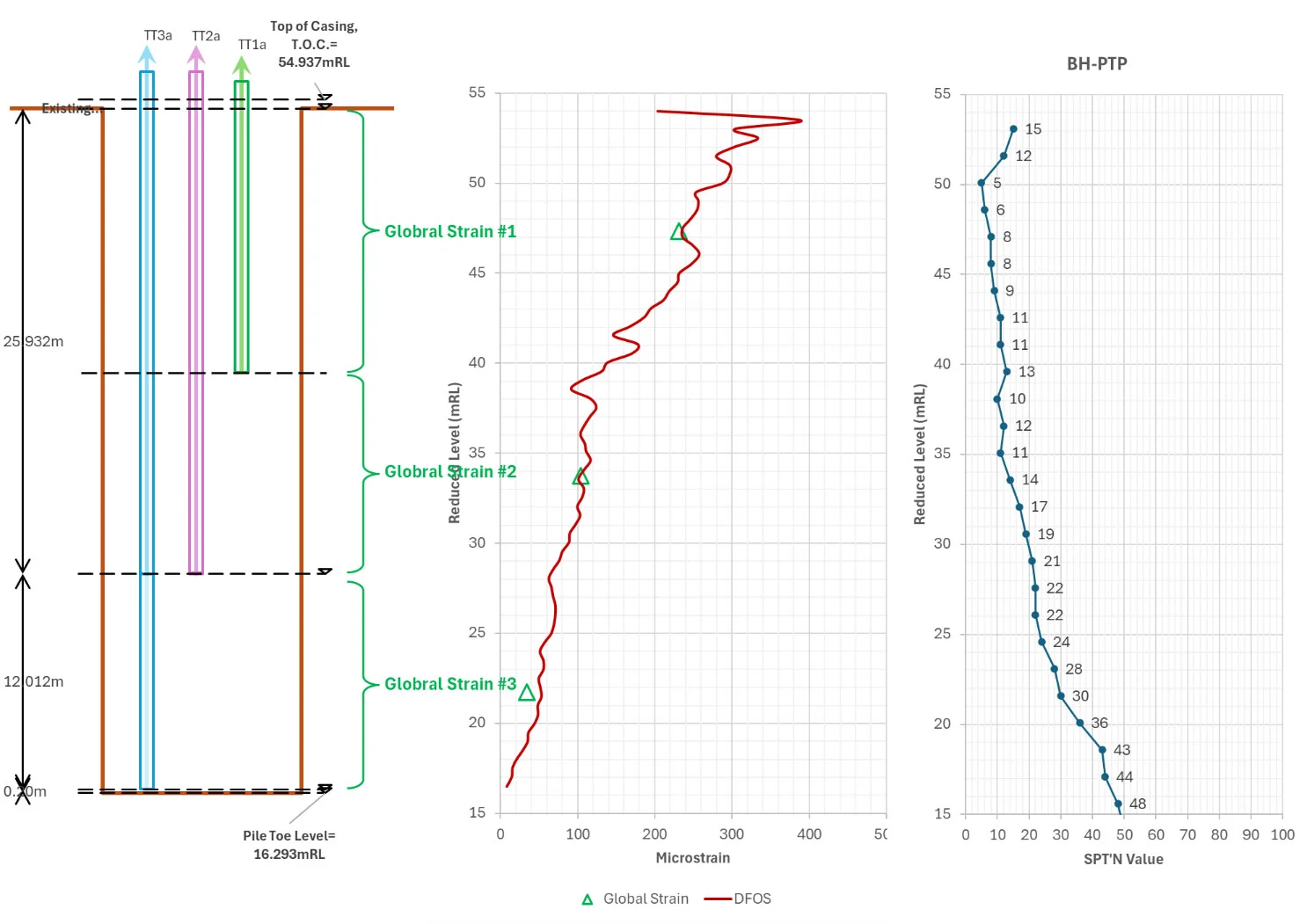

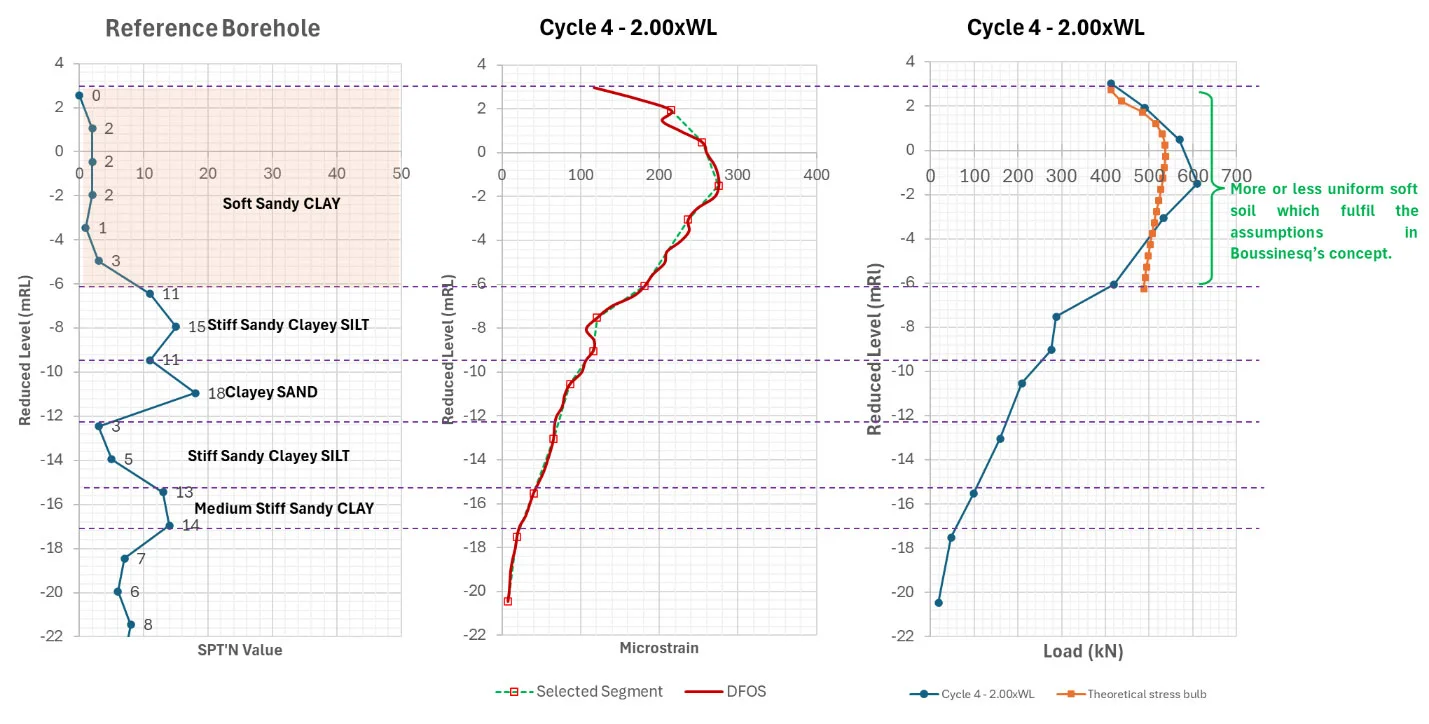

DFOS Instrumented Bored Pile in a Static Load Test

In this project, Geonamics deployed Distributed Fibre Optic Sensing (DFOS) on a bored pile to evaluate its load transfer characteristics under a static maintained load test. DFOS cables were carefully installed along the reinforcement cage from the pile head down to the toe, enabling full-length strain profiling throughout the loading and unloading cycles. The Brillouin Optical Frequency-Domain Analysis (BOFDA) method was adopted, offering a high-resolution measurement of strain along the pile.

The continuous strain profile obtained using DFOS allowed for accurate interpretation of the mobilized shaft resistance and end-bearing at the pile toe. Load-transfer (t-z and q-z) curves were constructed, offering valuable insights into the interaction between pile and surrounding soil. Notably, the strain measured by DFOS closely matched the global strain deduced from tell-tale instrumentation, validating DFOS as a reliable and advanced alternative. Compared to conventional strain gauges, which are limited to discrete measurement points, DFOS provided a complete and uninterrupted strain profile—revealing subtle transitions in soil stratigraphy and mechanical behavior that would otherwise go undetected. This project underscores the powerful role DFOS plays in modern pile testing and foundation performance verification.

DFOS Instrumented Driven Concrete Pile in a Static Load Test

In a unique application involving precast driven concrete piles, Geonamics implemented a DFOS monitoring system by integrating an internal steel tube within the pile cross-section. The 250 mm x 250 mm reinforced concrete piles were prefabricated with a central void to accommodate the optical fiber cable, which was grouted post-installation to ensure structural integrity. This design enabled non-intrusive DFOS installation after pile driving.

The load test was conducted using a jack-in machine as the reaction system—an unconventional yet practical solution on the project site. The DFOS system captured continuous strain profiles throughout the pile length during the load test, revealing a noteworthy influence of the jack-in machine’s reaction system. Specifically, strain anomalies indicative of boundary effects were detected, demonstrating how load distribution could be altered by sleeper length and contact configuration.

This case study exemplifies how DFOS goes beyond conventional instrumentation by offering spatial resolution that can capture interaction effects between testing systems and pile performance. Geonamics’ innovative adaptation of DFOS in a driven pile setup, paired with practical engineering judgement in interpreting results, made this project a standout example in advanced pile instrumentation.

A Maintained Load Test on an Extensometer A-9 Instrumented Bored Pile

In this project, Geonamics deployed a modified Geokon Model A-9 extensometer system to instrument a bored pile subjected to a conventional maintained load test (MLT). The goal was to directly assess pile-soil interaction by capturing the axial deformation at designated intervals along the pile shaft. The extensometer was installed with multiple anchoring points at predetermined depths, allowing localized measurements of relative movement between segments.

During the MLT, loading was applied in stages up to the target maximum test load, with readings recorded at each loading and unloading increment. The relative displacement between extensometer anchors enabled the calculation of global strain over each instrumented segment. These strain values were subsequently used to derive the mobilized unit shaft friction and end-bearing resistance through load transfer analysis.

This instrumentation approach provided a high-resolution profile of load distribution along the pile, revealing variations in soil stiffness and the mobilization of resistance with increasing load. Compared to conventional methods relying solely on pile head measurements, the A-9 extensometer offered insight into load settlement mechanisms at depth—critical for refining pile design and understanding behavior in layered soil formations.

Geonamics’ ability to customize the extensometer installation and interpret segmented deformation data exemplifies our commitment to delivering precise, project-specific instrumentation solutions that enhance engineering decision-making.

A Resistance-type Strain Gauges Instrumented Marine Bored Pile in a Statnamic Load Test

In this project involving marine infrastructure, Geonamics instrumented a bored pile with high-frequency resistance-type strain gauges to monitor behavior under a Statnamic load test. The marine pile was subject to rapid loading using the Statnamic method, which exerts a transient load of approximately 150–250 milliseconds in duration—suitable for evaluating piles in conditions resembling static loads.

Strain gauges were installed at various levels along the reinforcement cage prior to concreting. Their ability to record data at high sampling frequencies enabled the precise capture of strain development throughout the loading pulse. The measured strain data was then analyzed using the unloading point method to compute the equivalent static load transfer curve, showing both mobilized shaft friction and end-bearing resistance.

This test exemplifies how high-resolution dynamic measurements can be transformed into meaningful static interpretations, even in challenging marine environments. Geonamics demonstrated its capability to execute complex instrumentation procedures offshore while delivering high-quality data to assess pile behavior, ensuring client confidence in design assumptions and structural safety.

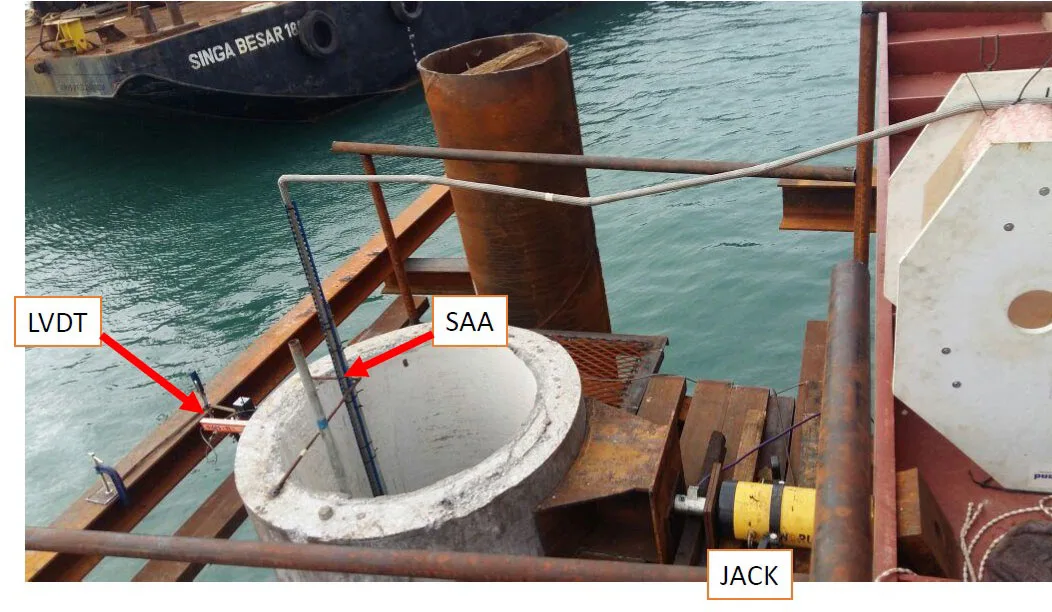

Lateral Pile Load Test on a Spun Pile

To evaluate the lateral capacity and stiffness of a spun pile, Geonamics employed a Shape Accel Array (SAA) to monitor the deflected shape of the pile under lateral loading. The SAA was inserted into a pre-installed casing within the pile to capture deflection profiles with high precision along the pile length. In parallel, a Linear Variable Differential Transformer (LVDT) was mounted at the pile head to measure surface-level lateral displacement as a reference.

A hydraulic jack applied lateral force to the pile, and a calibrated load cell was used to record applied loads in real-time. SAA readings offered detailed insights into lateral movement at varying depths, enabling the identification of the point of fixity and how load was distributed through the soil. Results from the SAA and LVDT showed strong agreement, validating the reliability of both instruments.

Compared to conventional inclinometers, SAA provided superior resolution and automated data acquisition. This project showcased Geonamics’ ability to design and implement an integrated monitoring system that delivered complete, reliable, and interpretable data on lateral pile behavior under field conditions.

A Prefabricated "Soft Toe" in an Instrumented Bidirectional Static Load Test

In a distinctive Bidirectional Static Load Test (BDSLT), a prefabricated “soft toe” is introduced at the base of the pile to isolate and analyze the shaft resistance along the lower segment. The soft toe was created by incorporating a 300 mm thick polystyrene block at the bottom of the reinforcement cage prior to concreting. This intentional weak zone prevented end-bearing resistance from developing during the test.

Several Vibrating Wire Strain Gauges (VWSG) were installed along both the upper and lower shaft sections of the pile to capture mobilized strain during jack activation. Upon load application, the system showed near-symmetric upward and downward displacements, confirming effective jack operation in mobilizing the resistance of upper and lower pile length. Notably, very minimal strain was observed at the pile toe, validating the soft toe’s ability to suppress end-bearing mobilization.

An unexpected yet valuable observation was that all VWSGs above the soft toe exhibited compressive strain, suggesting that even insignificant mobilized toe resistance, compression was being transferred through the lower shaft. This case highlights an innovative approach to isolating specific pile resistances and generating deeper understanding through purposeful structural modification and precise instrumentation.

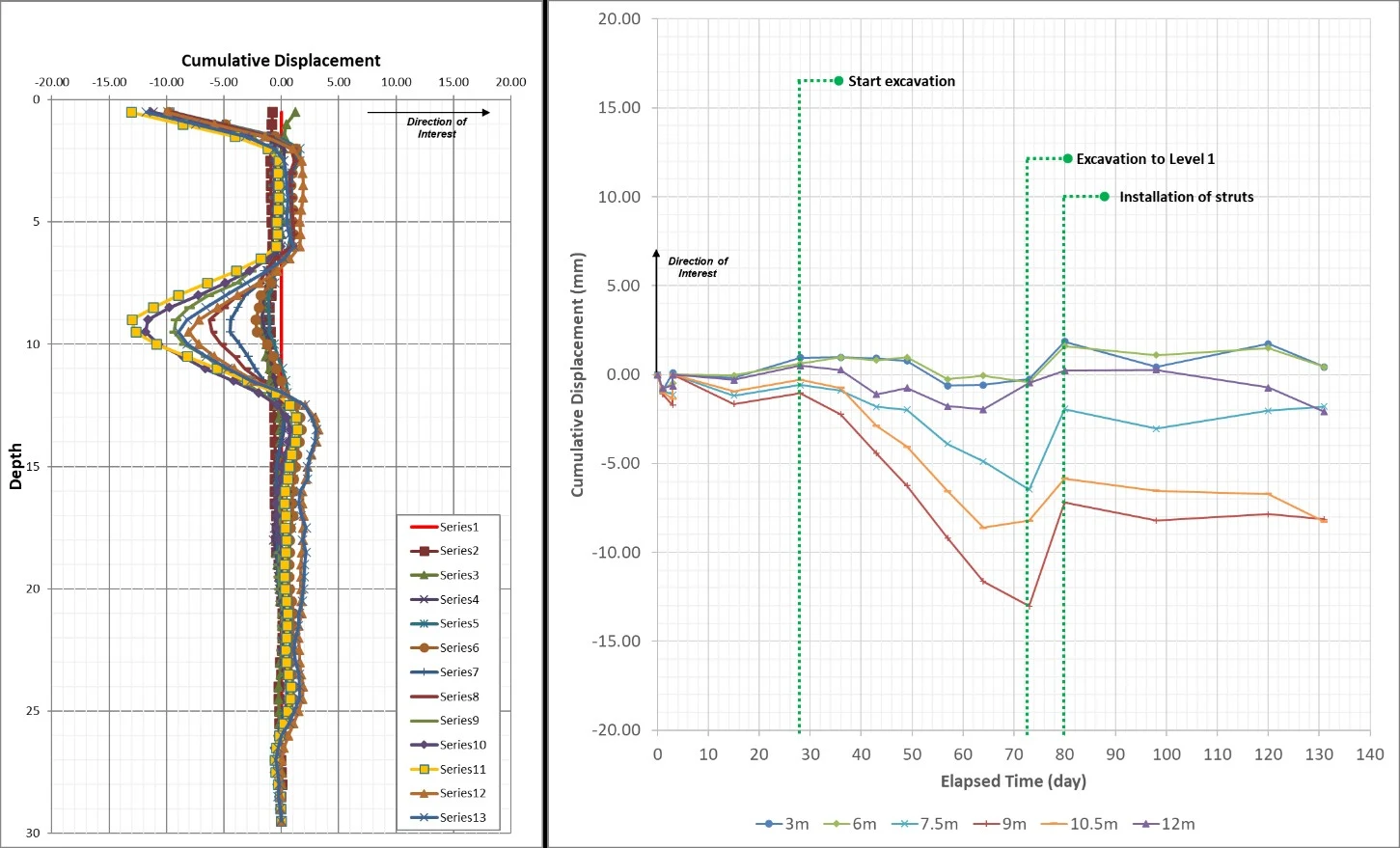

Inclinometer Measurement of Retaining Structure in Deep Excavation

In a deep basement excavation reaching a depth of 30 meters, Geonamics installed automated inclinometer systems to monitor horizontal movements of the’’ retaining wall. The inclinometer casing was placed vertically behind the wall and anchored into stable ground to serve as a reference. Periodic probe readings were taken throughout excavation stages to track lateral deformation of the wall.

Data showed incremental movements correlating with excavation depth and support installation stages. These measurements allowed engineers to verify wall behavior against predicted models, adjust excavation sequences, and fine-tune strutting systems in real-time. The success of this monitoring campaign exemplifies the importance of inclinometer in deep excavation risk management. Our systematic installation, regular data acquisition, and interpretative support helped ensure excavation safety and structural stability in a challenging urban environment.

Vibration Monitoring for Statnamic Load Tests

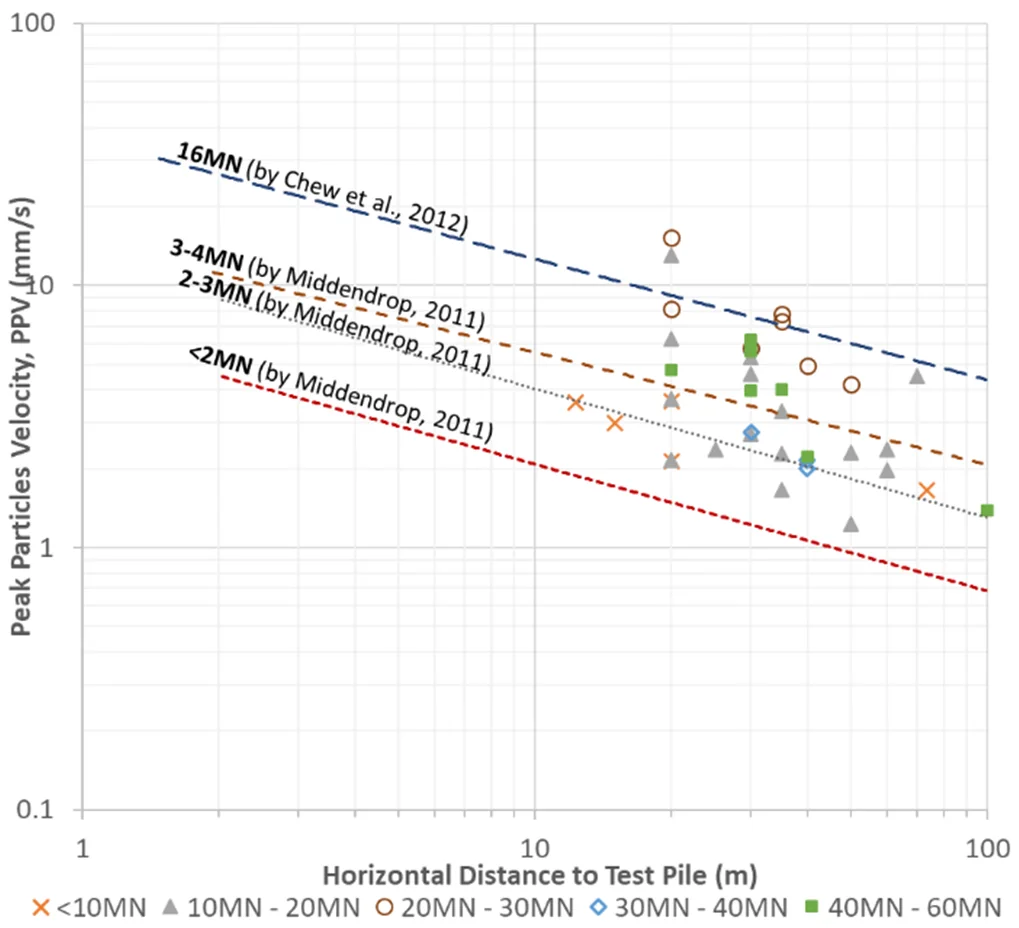

Statnamic Load Testing generates strong transient ground vibrations, raising concerns for nearby structures—especially those housing vibration-sensitive equipment. Geonamics has systematically monitored and analyzed these vibrations using accelerometers placed at various radial distances from test piles.

The monitoring process records Peak Particle Velocity (PPV) and other dynamic parameters at different distances, enabling us to build empirical profiles of vibration attenuation. Over multiple projects, Geonamics has compiled a comprehensive database correlating pile dimension, condition of pile termination, testing load and distance to test pile with resulting ground vibration levels.

This database provides valuable insights for designers seeking to assess vibration risk and determine safe distances for Statnamic testing. Our monitoring work has supported testing campaigns near critical infrastructure. This case reference underlines our commitment to integrating safety and environmental considerations into advanced pile testing methodologies.

A Comparison of Statnamic Load Test and Conventional Maintained Load Test

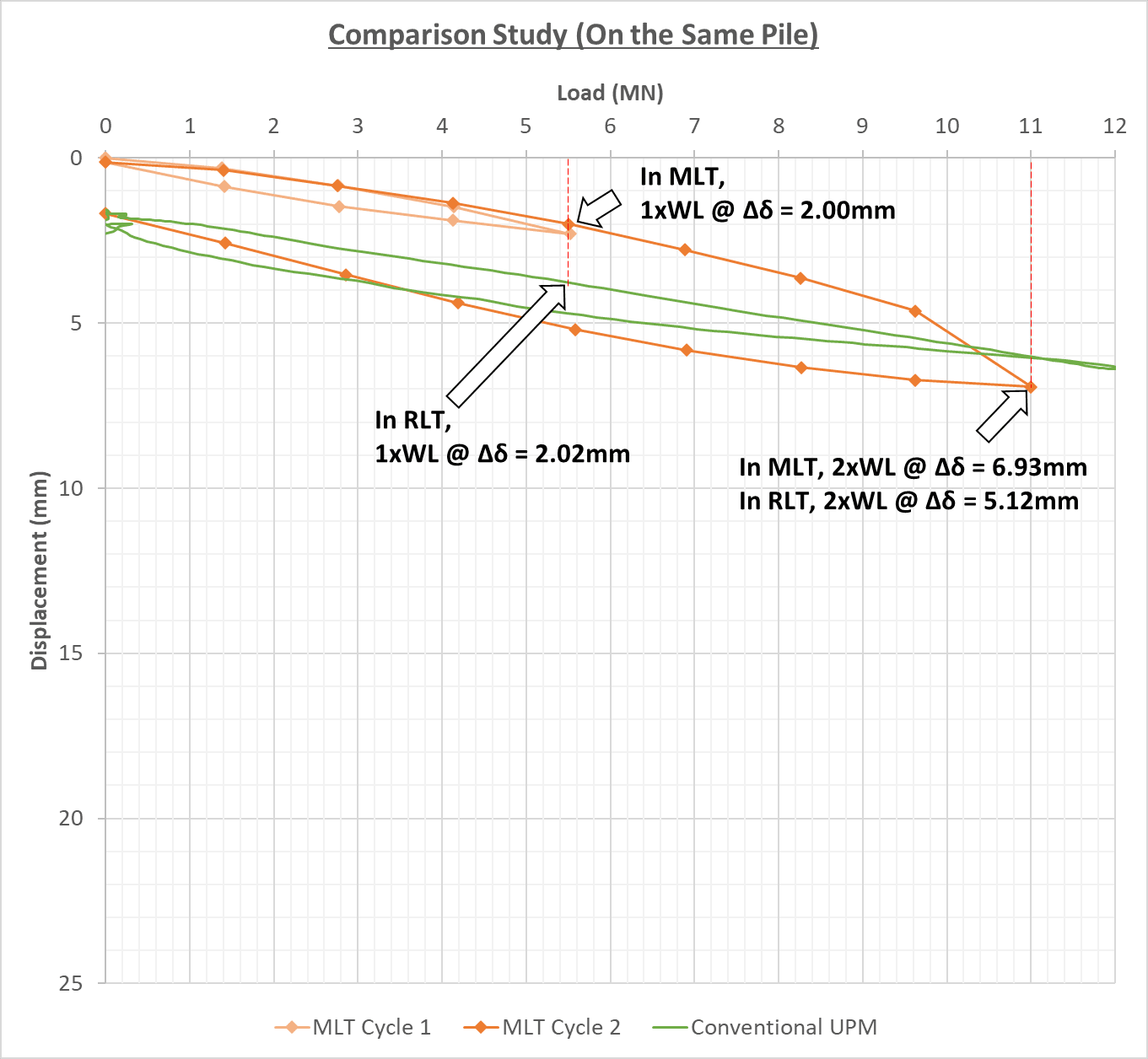

Geonamics conducted a comparative evaluation of a Statnamic Load Test (STN) and a Conventional Maintained Load Test (MLT) on the same test pile to assess the consistency and reliability of Statnamic testing in replicating static load behavior. Although past studies in Malaysia and Singapore have supported the equivalence of both methods, this case study further strengthens that position by providing real-world, side-by-side field data for validation.

The pile was initially tested using the conventional MLT method in two full cycles. In Cycle 1, the pile experienced a maximum settlement of 2.30 mm under an applied load of 5,500 kN (100% Working Load), with a residual settlement of 0.13 mm after unloading. In Cycle 2, the pile recorded a settlement of 6.93 mm at 11,000 kN (200% Working Load), and a residual settlement of 0.38 mm. These MLT results were carefully documented and plotted for comparison. Subsequently, a Statnamic Load Test was performed on the same pile. Load-settlement data from both tests were tabulated and graphically compared. The results revealed strong agreement between the two testing methods, particularly at higher load levels. The settlement responses recorded by STN closely matched those of MLT without requiring any empirical correction factors.

This case study demonstrates the viability of Statnamic Load Testing as a reliable alternative to conventional static testing in similar geological conditions. It also exemplifies Geonamics’ commitment to validation through empirical comparison and data transparency. As more case histories accumulate, such comparisons serve as a living reference to guide future foundation design and testing strategies.

Structural Health Monitoring Case References

Railway Track Load Test

In a railway infrastructure project, Geonamics conducted a full-scale load test on a track system. Shape Accel Array (SAA) and Vibrating Wire Strain Gauges (VWSG) were used to monitor ground movement and rail support behavior. SAA was installed beneath the sleeper units to detect settlement and deflection, while VWSGs were embedded in the foundation slab to track internal strain under repeated train-like load applications.

This dual-sensor approach provided comprehensive data on both soil-structure interaction and structural stress performance. The data enabled engineers to validate the load-bearing capacity and assess the resilience of the track structure system to dynamic loads. Geonamics’ instrumentation approach ensured the design assumptions were verifiable under simulated operational conditions, ensuring safer and more reliable railway operations.

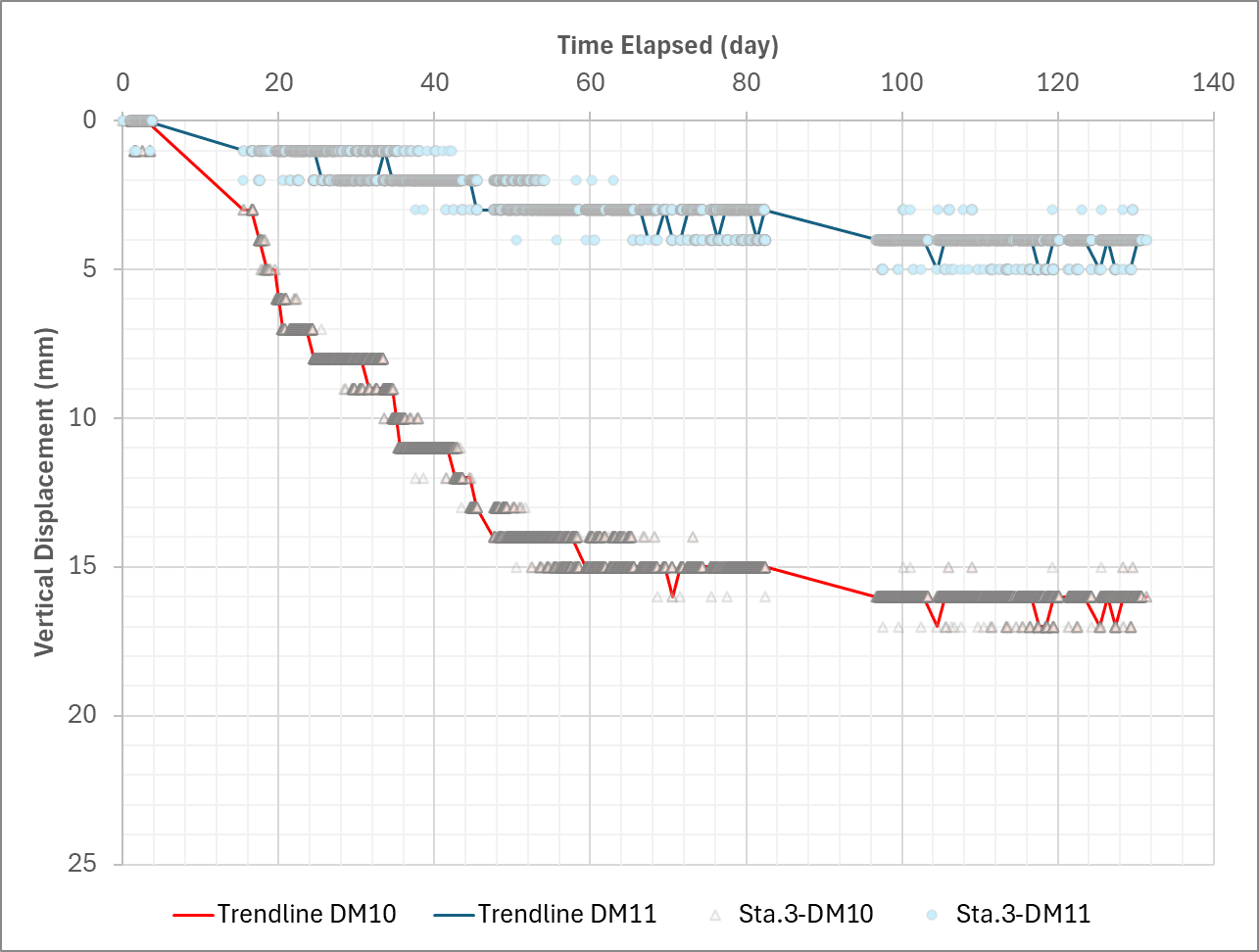

Settlement Monitoring for Stacking Load Test in Container Port

As part of the development of a container stacking yard, Geonamics deployed a Shape Accel Array (SAA) system to monitor the settlement of the foundation slab under loading from stacked containers. SAA sensors were installed beneath the concrete sleepers to track differential and overall settlement over time.

The project’s goal was to verify the uniformity and bearing performance of the foundation system under operational loading. The data captured by SAA enabled early detection of any localized settlement zones or subgrade irregularities, allowing for corrective actions before full operation.

This case highlighted the importance of ground instrumentation in heavy-duty port facilities and demonstrated Geonamics’ expertise in delivering high-resolution deformation profiles even under operational constraints.

Pilot Test on Launching of Prefabricated Concrete Girder

Geonamics played a key role in a proof load test involving prefabricated concrete pier caps. Two mock-up pier caps were constructed—one for evaluating concrete stitching quality (Mock-Up #1), and the other for a full-scale load simulation (Mock-Up #2) using progressively placed U-girders. Ultrasonic Pulse Velocity (UPV) tests were performed pre- and post-loading to assess stitching integrity. Instrumentation included VWSGs, LVDTs, and optical prisms strategically placed on and within the mock-up structures. These sensors recorded strain, displacement, and structural response during each stage of loading and unloading.

The test validated the structural adequacy of the concrete stitching and confirmed the design capacity of the pier cap under simulated girder loads. Geonamics’ integration of non-destructive testing and structural instrumentation ensured the safety and constructability of this innovative bridge launching method.

Automatic & Real-Time Monitoring of Structures

In a high-sensitivity environment, Geonamics implemented an automatic real-time monitoring system using a robotic total station. The system was configured to monitor displacement on critical points of a structure undergoing nearby construction activities. The robotic total station was programmed for continuous measurement cycles, automatically logging data and triggering alerts when threshold displacements were exceeded. This real-time capability allowed project stakeholders to make immediate decisions regarding structural safety, halt works when needed, and reassess risk levels dynamically. Geonamics’ proficiency in deploying automated systems ensured a high degree of accuracy, responsiveness, and client confidence in managing construction impact on sensitive structures.

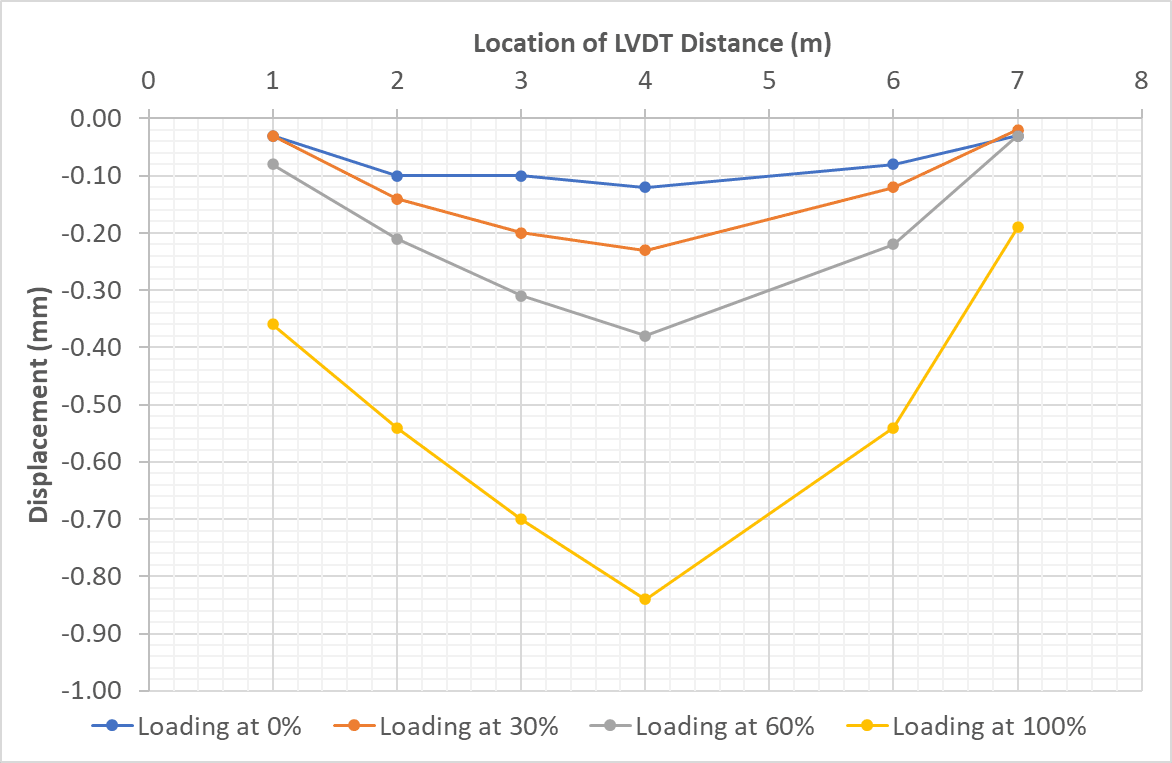

Static Load Test on Concrete Slab

A static load test was performed on a critical infrastructure slab to verify its capacity under service loading conditions. Geonamics instrumented the slab with LVDTs and Vibrating Wire Strain Gauges (VWSG) along both longitudinal and transverse directions underneath the slab. Crackmeters were also placed near pre-existing cracks to monitor any dimensional changes.

During the loading process, vertical displacement data from LVDTs and strain data from VWSGs were continuously recorded. The data provided insights into the slab’s stiffness, load distribution, and the effectiveness of reinforcement under actual loading. This monitoring program validated structural adequacy and supported the engineer’s decision to proceed with service operations. It further demonstrated Geonamics’ meticulous approach to structural verification through targeted instrumentation.

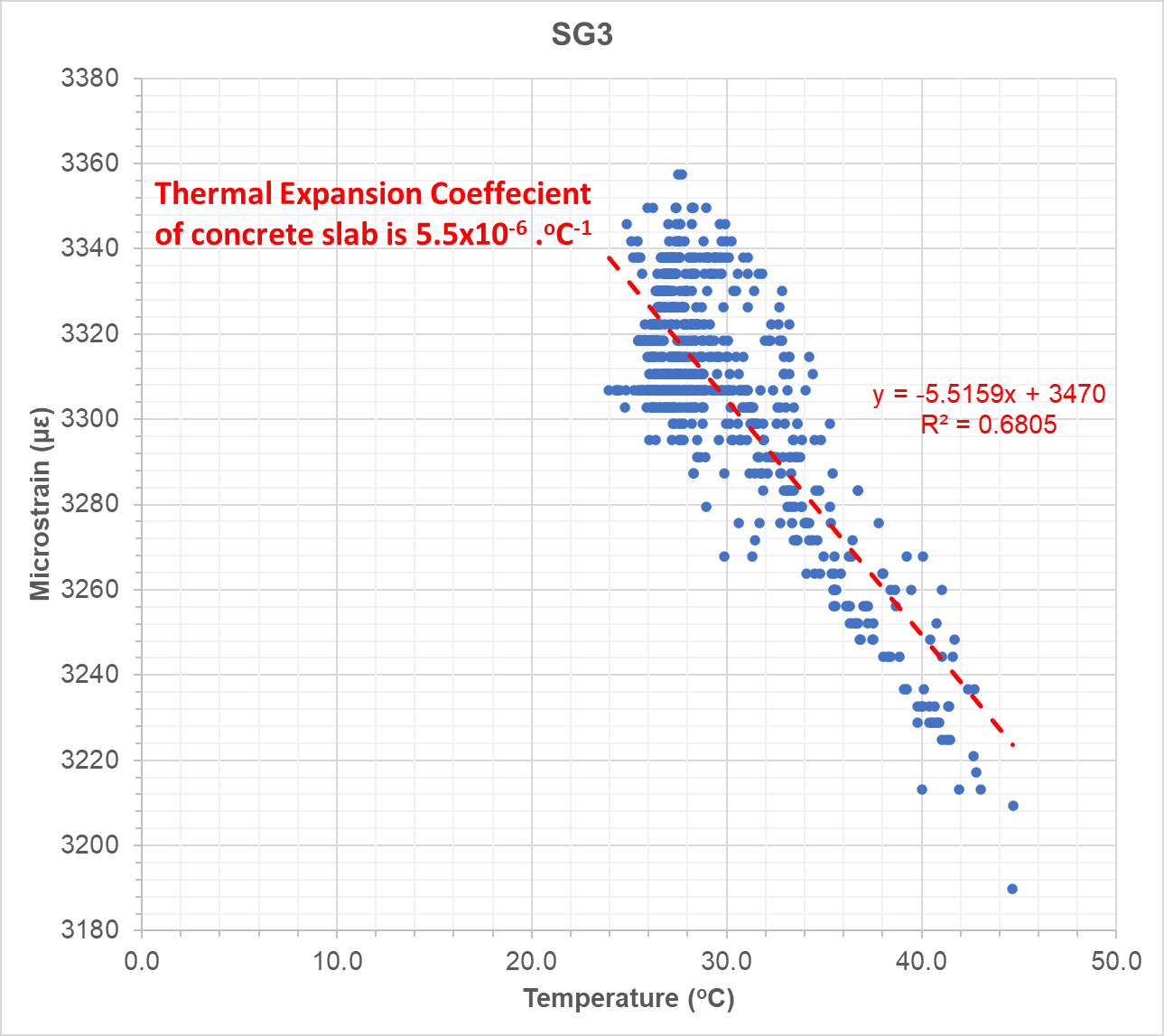

Thermal Expansion and Strain Monitoring on Concrete Slab

Responding to concerns over expansion-induced damage in a concrete slab with a pebble wash overlay, Geonamics installed three Vibrating Wire Strain Gauges to monitor thermal expansion. Measurements were taken at areas with and without observed pebble wash defects, allowing for comparative analysis.

The relationship between temperature changes and measured strain was plotted to determine the coefficient of thermal expansion. Results showed a coefficient of 14.8×10⁻⁶ °C⁻¹ in areas with defective overlay, and 5.2×10⁻⁶ °C⁻¹ where no defects were observed. Interestingly, the pebble wash layer showed minimal sensitivity to temperature variation. This investigation provided valuable insight into the role of differential thermal movement in causing overlay distress. Geonamics’ targeted instrumentation helped engineers quantify thermal effects and formulate corrective design measures.