Accredited Testing & Calibration Services for Geotechnical & Structural Excellence

Site Investigation

At Geonamics, we provide comprehensive Site Investigation Services tailored to meet the demands of on-shore, near-shore, and offshore construction projects. Our goal is to uncover critical subsurface details, ensuring that your project is built on a foundation of reliable, accurate, and realistic field data. All of our site investigations are conducted in strict accordance with the latest industry standards and codes of practice, including the Code of Practice for Site Investigation, BS 5930:2015+A1:2020 (British Standards Institution); Eurocode 7: Geotechnical design: General rules, BS EN 1997 – 1:2010 (2018) and Ground Investigation and testing, BS EN 1997 – 2:2010 (2020).

Our geotechnical investigations also adhere to the BS EN ISO standards for the identification and classification of soil and rock, such as BS EN ISO 14688-1:2018 and BS EN ISO 14688-2:2018 for soils, and BS EN ISO 14689:2018 for rock. We ensure compliance with the latest revisions of the relevant field-testing standards, including BS EN ISO 22475-1, BS EN ISO 22476-1 to BS EN ISO 22476-15, and the laboratory testing standards, such as BS EN ISO 17892-1 to BS EN ISO 17892-12. We provide a comprehensive and standardized approach to geotechnical investigation and testing. This rigorous adherence to industry standards assures that the data we provide is not only accurate but also consistent with internationally recognized practices. The services and testing scope we offer as below:

Offshore & Nearshore Investigation

Geotechnical investigations conducted offshore and nearshore present unique challenges due to varying weather conditions, strong currents, and unpredictable tidal flows. To ensure stable and reliable operations, it is critical to establish a secure working platform with minimal disruption to the surrounding environment. Unlike conventional temporary offshore platforms, we utilize jack-up barges as our primary working platform, offering superior stability, safety, and strength to withstand the harsh offshore and nearshore conditions.

A jack-up barge is a steel floating platform equipped with four long, retractable steel legs with spudcans. Upon reaching the designated location, the legs are lowered to the seabed, securely anchoring the platform at the optimal seabed level. This jack-up process elevates the platform above the waterline, eliminating the effects of waves and providing a stable investigation surface.

Hand Auger Boring

Hand auger boring is a simple and cost-effective method for performing shallow subsurface investigations. This technique involves manually drilling a small-diameter borehole using a hand auger to collect soil samples and observe soil conditions at depths typically up to 10 meters.

While less invasive and less expensive than other drilling methods, hand auger boring provides essential in-situ data on soil type and condition. This method is especially valuable in urban environments where access to larger machinery is restricted. The data collected enables engineers to assess the shallow subsurface and make informed decisions about foundation design and site preparation.

Rotary Drilling and Wash-Boring

Rotary drilling and wash-boring are advanced drilling techniques used for deeper geotechnical investigations, typically reaching depths beyond the capacity of standard auger methods. Rotary drilling uses a rotating drill bit to break through rock and other hard materials, while wash boring involves injecting water or air to clear debris from the borehole during drilling.

These in-situ methods provide detailed information about soil and rock layers at greater depths, critical for foundation design, underground structures, and other projects requiring deep investigations. The data helps engineers accurately assess soil and rock properties at depth for projects such as high-rise buildings, bridges, and tunnels.

Standard Penetration Test (SPT)

The Standard Penetration Test (SPT) is a widely used in-situ test designed to evaluate the strength and consistency of soils, particularly in granular soils such as sands and gravels. The test involves driving a split-barrel sampler into the soil at the bottom of a borehole using a standardized hammer. The number of blows required to drive the sampler a fixed distance (usually 300 mm) is recorded and known as the SPT N-value. As an in-situ method, the SPT provides valuable data that reflects the soil’s resistance to penetration under specific conditions. The SPT N-value is used to estimate important parameters such as soil bearing capacity. It is particularly useful for assessing the suitability of soils for shallow and deep foundations.

Cone Penetration Test (CPT)

Vane Shear Test

The Vane Shear Test is a simple and effective method for determining the in-situ shear strength of cohesive soils, particularly clays. The test involves inserting a four-bladed vane into the soil and rotating it to measure the torque required to shear the soil. The shear strength is directly related to the amount of torque needed to cause failure in the soil.

This in-situ test provides critical data on the soil’s shear strength, which is essential for evaluating the stability of slopes, embankments, and foundations. By measuring the soil’s resistance to shearing forces, the Vane Shear Test plays a pivotal role in preventing potential failures caused by weak soil conditions.

In-situ Soil Sampling

Soil sampling is a crucial activity in geotechnical investigations, providing essential information about the mechanical, physical and chemical properties of the subsurface soils. The process involves extracting undisturbed soil samples from various depths to analyze their composition, moisture content, strength, and other properties in a laboratory setting.

At Geonamics, we use a variety of soil sampling methods, carefully selected based on soil type, to ensure minimal disturbance during sample extraction. This ensures the integrity of the samples and allows for accurate laboratory testing. Our accredited laboratory verifies and assesses the properties and strength of the soil to support further project design and analysis. Our team is committed to delivering reliable, undisturbed soil samples with the least possible disturbance, ensuring that your project’s design is based on the most accurate and up-to-date subsurface information available.

Pressuremeter Test

The Pressuremeter test is a versatile in-situ testing method used to evaluate the deformability and strength of soils. The test involves inserting a cylindrical probe into the ground and inflating it within a borehole to measure the pressure required to cause the soil to deform. The results provide insights into the soil’s shear strength, stiffness, and ultimate bearing capacity.

This in-situ test is critical for assessing cohesive and granular soils, offering a comprehensive understanding of their stress-strain behavior. The data obtained through the Pressuremeter test helps engineers design foundations, slope stability, and other structures that account for soil stiffness characteristics.

Rock Probing

Rock probing is an essential in-situ method used to detect the bedrock level and assess its undulating formation. Unlike detailed soil stratigraphy investigations, the primary objective of rock probing is to provide an overall understanding of the bedrock’s depth and variation. This service is particularly valuable in areas with limestone formations, where the bedrock may exhibit significant undulations and hidden cavities. This allows engineers to detect variations in the bedrock level and identify the presence of cavities underneath, which is crucial for designing deep foundations and pre-planning conzstruction methods.

Engineers rely on rock probing data to make informed decisions about foundation design and to anticipate potential challenges, such as the need for additional support or specific construction techniques to handle undulating or cavernous bedrock. Geonamics’ expertise in rock probing ensures that your project will have a comprehensive understanding of the bedrock conditions, allowing for a more effective and safe design.

Mackintosh Probe / JKR Probe

The Mackintosh Probe (also known as the JKR Probe) is an in-situ test used to assess the consistency and shear strength of fine-grained soils, particularly soft clays. The test involves inserting a tapered probe into the soil and applying a constant load. The penetration resistance is measured as the probe is advanced, providing valuable insights into the soil’s compactness and strength characteristics.

This test is particularly useful in identifying the presence of weak layers within the soil profile and determining their suitability for foundation design. It is often employed when more precise geotechnical data is required for soft soils, where conventional tests may be less effective. The results from the Mackintosh Probe are used to estimate the undrained shear strength and bearing capacity of the soil, which is crucial for evaluating the stability of slopes and designing appropriate foundations.

Construction Materials Testing

At Geonamics, we provide a comprehensive range of construction materials testing services to ensure the quality, durability, and compliance of materials used in infrastructure and construction projects. Our laboratory is accredited by the Department of Standards Malaysia (DSM) in accordance with MS ISO 17025, demonstrating our commitment to high testing standards, reliability, and technical competence. Geonamics is also acknowledged as a Testing Body, and our testing reports under the accredited scopes under Schedule 4 are recognized by CIDB Malaysia. This recognition underscores the reliability of our test results, allowing engineers, contractors, and stakeholders to have full confidence in the materials used for their projects.

We conduct laboratory testing on soil, rock, aggregate, concrete, metallic materials, bituminous materials, scaffold, falseworks, and geosynthetic materials to assess their physical and mechanical properties. These tests are crucial for verifying material properties, suitability, ensuring compliance with local and international standards, and optimizing performance for engineering applications.

All testing procedures adhere to the latest revisions of MS, BS, ASTM, EN, ISO and standards, ensuring that results meet industry requirements. Our expert team carefully handles and analyzes each sample to provide accurate and reliable test data, supporting engineers and contractors in making informed material selection and design decisions.

Soil Testing

The Mackintosh Probe (also known as the JKR Probe) is an in-situ test used to assess the consistency and shear strength of fine-grained soils, particularly soft clays. The test involves inserting a tapered probe into the soil and applying a constant load. The penetration resistance is measured as the probe is advanced, providing valuable insights into the soil’s compactness and strength characteristics.

This test is particularly useful in identifying the presence of weak layers within the soil profile and determining their suitability for foundation design. It is often employed when more precise geotechnical data is required for soft soils, where conventional tests may be less effective. The results from the Mackintosh Probe are used to estimate the undrained shear strength and bearing capacity of the soil, which is crucial for evaluating the stability of slopes and designing appropriate foundations.

Rock Testing

Rock properties play a crucial role in projects involving tunnels, deep foundations, and slope stability. Geonamics performs unconfined compressive strength (UCS), point load strength index, modulus of elasticity, and durability testing on rock specimens to assess their mechanical properties and suitability for engineering applications.

Our laboratory follows ASTM D7012, ASTM D5731, and/or BS EN ISO 14689 for rock testing, ensuring data accuracy and compliance with international standards. Understanding rock strength and behavior allows engineers to design safe and efficient structures in rock formations.

Aggregate Testing

Aggregates are key components in concrete, asphalt, and road base materials, and their properties must be evaluated to meet performance standards. Geonamics offers a full suite of aggregate testing, including gradation analysis, aggregate impact value (AIV), aggregate crushing value (ACV), ten percent fines value (TFV), water absorption, flakiness index, elongation index and others. We adhere to BS 812, BS EN 933, BS EN 1097, and/or ASTM standards to ensure that aggregates meet strength, durability, and workability criteria. Our rigorous testing protocols help contractors and engineers select the right aggregates for long-lasting and high-performance construction.

Concrete Testing

Metallic Materials Testing

Metallic materials such as steel bars, wires, and plates are widely used in reinforced concrete structures and other engineering applications. Geonamics offers testing for tensile strength, bend performance, welded shear force, and mechanical coupler testing to verify compliance with construction standards. Our tests align with ISO 6892-1, BS EN ISO 15630, and ASTM E8/E8M, ensuring that metallic materials meet strength and ductility requirements. By providing high-precision testing, we support engineers in selecting durable and high-performance reinforcement materials.

Bituminous Materials Testing

Bituminous materials are essential for road pavements, bridges, and waterproofing applications. Geonamics performs Marshall stability, bulk density, flow tests, thickness measurements, and asphalt extraction tests to evaluate bitumen quality and durability. Our testing follows ASTM D6927, ASTM D2726, and/or BS EN 12591, ensuring compliance with highway and transportation specifications. By conducting detailed asphalt performance testing, we help ensure safe and long-lasting pavement construction.

Scaffold Testing

Scaffolds are temporary structures that provide essential support for construction activities at height, making their strength, stability, and safety compliance critical for worker protection. At Geonamics, we conduct comprehensive testing on scaffold tubes, couplers, fittings, and other components to ensure compliance with local material standards, specifically Construction Industry Standard 22 (CIS 22).

Our testing process evaluates the structural integrity and load-bearing capacity of scaffolding systems through a series of controlled tests. The results determine whether the scaffolding meets CIS 22 requirements, which is a key criterion for obtaining the Perakuan Pematuhan Standard (PPS) from CIDB Malaysia. With state-of-the-art facilities and accredited testing procedures, Geonamics ensures that scaffolding components comply with industry standards, helping contractors and developers enhance site safety and regulatory compliance.

Falseworks Testing

Falseworks are temporary support structures used to sustain formwork, loads, and construction elements until they gain sufficient strength. Ensuring stability, load-bearing capacity, and material quality of falseworks is crucial for construction safety and structural integrity. At Geonamics, we perform comprehensive falsework testing in accordance with Construction Industry Standard 23 (CIS 23). Our testing evaluates the strength, stability, and compliance of falsework components, ensuring they meet regulatory requirements for safe temporary support in construction projects.

Compliance with CIS 23 is a key requirement for obtaining the Perakuan Pematuhan Standard (PPS) from CIDB Malaysia, verifying that falsework systems are fit for purpose and meet industry safety standards. With accredited testing procedures and a team of experienced specialists, Geonamics provides reliable assessments that help contractors and engineers ensure safe and compliant construction practices.

Geosynthetic Materials Testing

Geosynthetics are widely used in soil stabilization, drainage, and erosion control applications. Geonamics provides varies tensile strength, puncture resistance, permeability, and durability tests or geotextiles, and geogrids. Our testing complies with ASTM D4595, BS EN ISO 10319, and relevant geosynthetic standards, ensuring materials perform effectively in geotechnical applications. Through comprehensive geosynthetic testing, we support engineers in selecting suitable materials for sustainable and durable construction.

Non-destructive Testing

Non-Destructive Testing (NDT) plays a crucial role in assessing the integrity, durability, and safety of building structures without causing damage to the material being tested. These tests provide valuable insights into concrete strength, reinforcement details, and structural performance, ensuring compliance with design specifications and early detection of potential issues.

At Geonamics, we offer a range of advanced NDT techniques tailored for building structural assessment, allowing engineers to evaluate in-situ conditions accurately. Our highly trained specialists conduct tests using the latest international standards and best practices, delivering precise and reliable data to support informed decision-making in construction and structural rehabilitation projects. The following NDT methods are available:

Ultrasonic Pulse Velocity (UPV) Test

Scaffolds are temporary structures that provide essential support for construction activities at height, making their strength, stability, and safety compliance critical for worker protection. At Geonamics, we conduct comprehensive testing on scaffold tubes, couplers, fittings, and other components to ensure compliance with local material standards, specifically Construction Industry Standard 22 (CIS 22).

Our testing process evaluates the structural integrity and load-bearing capacity of scaffolding systems through a series of controlled tests. The results determine whether the scaffolding meets CIS 22 requirements, which is a key criterion for obtaining the Perakuan Pematuhan Standard (PPS) from CIDB Malaysia. With state-of-the-art facilities and accredited testing procedures, Geonamics ensures that scaffolding components comply with industry standards, helping contractors and developers enhance site safety and regulatory compliance.

Electromagnetic Covermeter Test

The Electromagnetic Covermeter Test is an NDT technique used to determine the depth of concrete cover over embedded reinforcement bars (rebar). It detects the location, diameter, and distribution of rebars by measuring changes in electromagnetic fields. This test is essential for verifying whether the concrete cover thickness meets design and durability requirements, preventing issues such as corrosion risk and inadequate reinforcement protection. It is widely applied in structural inspections, compliance checks, and repair planning. Geonamics utilizes high-precision electromagnetic covermeters to deliver accurate and reliable reinforcement assessments, ensuring compliance with BS 1881-204 and/or ASTM G59.

Rebar Scanning & Mapping Test

The Rebar Scanning and Mapping Test provides a detailed visualization of reinforcement layout within concrete structures. Using advanced electromagnetic scanning technology, this method identifies rebar positioning, spacing, diameter, and depth with high accuracy. This non-destructive approach is crucial for as-built verification, structural condition assessment, and pre-drilling inspections, reducing the risk of damaging embedded reinforcement during renovation or retrofitting works. At Geonamics, we employ state-of-the-art rebar scanning and mapping technology to produce comprehensive reinforcement layouts, aiding engineers in structural evaluation and design verification.

Rebound Hammer Test

The Rebound Hammer Test, also known as the Schmidt Hammer Test, is a rapid and non-destructive method for estimating in-situ concrete strength. This test involves striking the concrete surface with a spring-loaded hammer and measuring the rebound number, which correlates to the concrete’s compressive strength. While the Rebound Hammer Test provides a quick assessment of concrete hardness, it is often used alongside other strength evaluation methods to obtain a more comprehensive understanding of structural integrity. Geonamics performs Rebound Hammer Testing in accordance with BS EN 12504-2 and/or ASTM C805, ensuring reliable and consistent results for concrete condition assessments.

Windsor Probe Test

The Windsor Probe Test is a semi-destructive method for estimating the compressive strength of in-situ concrete. This test involves driving hardened steel probes into the concrete surface under controlled conditions. The penetration depth is then correlated to concrete strength, providing valuable data for structural assessment. This method is particularly useful for evaluating older structures, verifying concrete strength in-situ, and assessing uniformity in large areas where core sampling may not be feasible. At Geonamics, we conduct Windsor Probe Testing in compliance with ASTM C803, delivering accurate and repeatable strength assessments for various concrete structures.

Anchor Pullout Test

The Anchor Pullout Test evaluates the load-bearing capacity and bond strength of anchors, bolts, and fixings embedded in concrete or masonry. This test involves applying a controlled tensile load to the anchor and measuring its resistance to pullout forces. The test is widely used in structural retrofitting, safety verification of anchorage systems, and compliance checks for fixing installations. Engineers rely on pullout test results to assess anchorage reliability in high-load applications. Geonamics conducts Anchor Pullout Testing in accordance with BS 8539 and/or ASTM E488, ensuring safe and effective anchorage performance in construction projects.

Deep Foundations Testing

Deep foundation systems play a critical role in supporting high-rise buildings, bridges, and heavy infrastructure by transferring structural loads to competent soil or rock layers. Geonamics provides a full spectrum of geotechnical testing services to evaluate deep foundation performance under design loads, structural integrity, and design parameter verification. These tests ensure that foundations meet engineering specifications and comply with industry standards, minimizing risks associated with foundation failure and excessive settlement.

Our deep foundation testing services adhere to the latest BS EN ISO and ASTM standards, ensuring that test results are accurate, reliable, and compliant with international best practices. The following testing methods are available:

Static Load Test (SLT)

The Static Load Test (SLT) is the most fundamental method for assessing the bearing capacity and settlement behavior of a deep foundation under controlled loading conditions. By providing a kentledge or reaction means, this test involves applying a gradual compression load onto a pile and monitoring its displacement response over time. SLT provides direct measurements of pile performance, validating design assumptions regarding axial capacity and settlement characteristics. Engineers use SLT results to confirm pile safety factors, optimize foundation design, and ensure compliance with project specifications. At Geonamics, we conduct Static Load Testing in accordance with BS EN ISO 22477-1, ensuring high-quality and reliable test results that support sound geotechnical engineering decisions.The Anchor Pullout Test evaluates the load-bearing capacity and bond strength of anchors, bolts, and fixings embedded in concrete or masonry. This test involves applying a controlled tensile load to the anchor and measuring its resistance to pullout forces. The test is widely used in structural retrofitting, safety verification of anchorage systems, and compliance checks for fixing installations. Engineers rely on pullout test results to assess anchorage reliability in high-load applications. Geonamics conducts Anchor Pullout Testing in accordance with BS 8539 and/or ASTM E488, ensuring safe and effective anchorage performance in construction projects.

Bidirectional Static Load Test (BDSLT)

The Bidirectional Static Load Test (BDSLT) is another innovative approach of the conventional SLT, utilizing a hydraulic jack system embedded within the pile at a “balanced” location along the pile shaft. This method effectively mobilizes the shaft resistance and toe resistance of the pile itself as reactions to achieve the equivalent designated load at the pile top. The capacity of hydraulic jacks in BDSLT is only half of conventional SLT without any kentledge or reactions system at the pile top. The detailed understanding of load distribution along the pile length and toe resistance can be attained with preinstallation of additional instruments in the pile. BDSLT is particularly useful for testing large-diameter bored piles, and barrettes, where conventional static loading may be impractical due to space or load constraints. Geonamics performs BDSLT in compliance with BS EN ISO 22477-1, ensuring accurate assessment of deep foundation performance while maintaining efficiency and cost-effectiveness in testing procedures.

Rapid Load Test (RLT) - Statnamic & StatRapid

The Rapid Load Test (RLT) is an economical alternative to conventional static load testing, providing efficient and reliable assessment of pile load capacity with significantly reduced testing time and cost. RLT can be performed using two primary methods:

- Statnamic Load Test – Utilizes a controlled reaction mass launch to generate an equal and opposite axial force on the pile.

- StatRapid Load Test – Employs a specially designed cushion system to prolong the deceleration of an impact load, thereby generating a gradual axial force on the pile.

Both methods ensure that the applied force duration is sufficiently long to induce a quasi-static response in the test pile. The applied pile head load is measured using load cells, while the corresponding settlement is recorded independently via high-precision laser displacement sensors. This allows for the evaluation of the pile’s load-settlement behavior under test conditions.

Theoretical methodologies for deriving equivalent static load-settlement behavior from RLT data have been well-established through extensive research and international testing standards. RLT is particularly advantageous for projects requiring fast-track foundation verification, offering a rapid, reliable, and cost-effective solution for pile capacity assessment. Geonamics have more than 20years experience and conducts Rapid Load Testing in accordance with BS EN ISO 22477-10, ensuring high-precision and dependable load evaluation for deep foundation systems.

High Strain Dynamic Load Test (HSDLT or PDA Test)

Cross-hole Sonic Logging (CSL) Test

The Cross-hole Sonic Logging (CSL) Test is a non-destructive method for assessing the structural integrity of deep foundation elements such as bored piles and diaphragm walls. The test involves transmitting ultrasonic pulses between pre-installed access tubes within the pile to detect voids, cracks, inclusions, or defects. CSL is particularly valuable in quality control of cast-in-place concrete piles, ensuring that the constructed foundation meets structural integrity requirements. Geonamics conducts CSL Testing in compliance with ASTM D6760 and coupled with latest DFI (2019) assessment criteria to deliver a high-resolution integrity assessments for deep foundation systems.

Low Strain Dynamic Load Test (LSDLT or PIT)

The Low Strain Dynamic Load Test (LSDLT), also known as the Pile Integrity Test (PIT), is a cost-effective method for assessing pile integrity and continuity. The test involves applying a small impact to the pile head while analyzing the stress wave reflections to detect potential cracks, voids, or length anomalies. LSDLT is widely used in quality control and forensic investigation of deep foundations, providing rapid and reliable integrity assessments. Geonamics conducts LSDLT in accordance with ASTM D5882, ensuring accurate and dependable pile condition evaluations.

Shaft Area Profile Evaluator (SHAPE) Test

The Shaft Area Profile Evaluator (SHAPE) Test is an advanced ultrasonic method used to evaluate the verticality, diameter, and shape of bored piles or drilled shafts. This test provides detailed cross-sectional imaging of the pile, helping engineers identify anomalies, and the verticality of the pile shaft. Geonamics performs SHAPE Testing in compliance with ASTM D8232, delivering high-precision measurements for deep foundation evaluations.

Lateral Pile Load Test

The Lateral Pile Load Test evaluates a pile’s resistance to horizontal loads, which is critical for structures subjected to wind forces, seismic activity, or lateral soil movements. This test applies a controlled horizontal force to the pile while measuring its lateral deflection and stiffness behavior. Lateral pile load testing ensures that foundations can withstand lateral forces without excessive displacement, supporting the safe design of bridges, towers, and waterfront structures. At Geonamics, we conduct Lateral Pile Load Testing with precision instrumentation, ensuring reliable results for foundation stability assessments.

Plate Bearing Test

The Plate Bearing Test is an in-situ method used to determine the bearing capacity and settlement behavior of subgrade soil, compacted fill, and shallow foundations. The test involves applying a gradual load on a steel plate placed on the ground surface while monitoring the settlement response. Plate bearing tests are widely used in pavement design, temporary structures, and shallow foundation assessments to verify load-bearing suitability. Geonamics conducts Plate Bearing Tests in compliance with BS and/or ASTM standards, ensuring accurate soil stiffness and strength evaluations for construction projects.

Geophysical Testing

Geophysical testing is a non-invasive and cost-effective method for evaluating subsurface conditions by utilizing seismic and electrical properties of the ground. These tests provide valuable insights into soil and rock stratigraphy, subsurface anomalies, groundwater conditions, and engineering properties without the need for extensive drilling. At Geonamics, we utilize advanced geophysical techniques to support a variety of geotechnical and geological investigations. These methods are particularly useful in foundation engineering, site characterization, seismic hazard assessments, and underground utility detection.

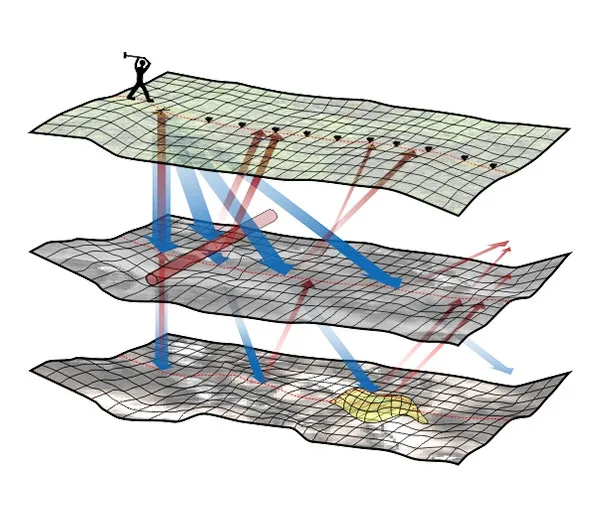

Seismic Reflection Test

The Seismic Reflection Test is a geophysical technique used to map deep subsurface structures by analyzing the reflection of seismic waves at geological boundaries. This method is particularly useful for detecting faults, bedrock profiles, subsurface voids, and stratigraphic variations. During the test, seismic waves are generated at the surface and travel through the subsurface layers. When these waves encounter a contrast in material properties, a portion of the energy is reflected back to surface receivers (geophones or hydrophones). The recorded data is then processed to create detailed subsurface images, aiding engineers in foundation design and geological assessments. Geonamics performs Seismic Reflection Testing in compliance with ASTM D5753, ensuring accurate subsurface profiling for engineering and environmental studies.

Seismic Refraction Test

The Seismic Refraction Test is an effective method for determining the depth to bedrock, soil stratigraphy, and rippability of rock formations. This test measures the travel time of seismic waves as they pass through different subsurface layers, providing valuable information about layer velocities and material stiffness. This method is widely used in foundation engineering, slope stability studies, and infrastructure development to assess subsurface stiffness and potential weak zones. Geonamics conducts Seismic Refraction Testing in accordance with ASTM D5777, delivering reliable and high-resolution geophysical data to support geotechnical engineering projects.

Multichannel Analysis of Surface Waves (MASW)

The Multichannel Analysis of Surface Waves (MASW) is a non-invasive seismic method used to evaluate shear wave velocity profiles of the subsurface. Shear wave velocity is directly related to soil stiffness and seismic site classification, making MASW a crucial tool for earthquake engineering, ground improvement studies, and foundation design. MASW involves generating low-frequency seismic waves and recording the surface wave propagation using an array of geophones. The collected data is processed to develop a shear wave velocity profile, helping engineers understand subsurface stiffness variations. Geonamics performs MASW testing in compliance with ASTM D7158, ensuring accurate shear wave velocity assessments for seismic site characterization.

Soil Resistivity Mapping

Soil Resistivity Mapping is an electrical geophysical method used to assess the variations in subsurface resistivity, which is influenced by factors such as moisture content, soil composition, groundwater presence, and contamination levels. This method is commonly applied in groundwater exploration and geotechnical site investigations. By measuring resistivity distribution at various depths, engineers can infer subsurface conditions and make informed design decisions. Geonamics conducts Soil Resistivity Mapping in accordance with ASTM D6429, providing detailed subsurface resistivity profiles for engineering and environmental applications.

Downhole Seismic Test

The Downhole Seismic Test is a borehole geophysical method used to determine seismic wave velocities (P-wave and S-wave) at different depths. This test is essential for seismic hazard analysis, ground response studies, and soil-structure interaction assessments. During the test, a seismic energy source is triggered at the ground surface while receivers (geophones) placed at different depths in a borehole record the wave arrival times. This data is used to develop a depth-dependent velocity profile, aiding engineers in site-specific seismic design and liquefaction potential assessments. Geonamics performs Downhole Seismic Testing in compliance with ASTM D7400 and ASTM D8381, ensuring high-precision seismic velocity measurements for geotechnical and earthquake engineering applications.

Calibration

Calibration is essential for ensuring the accuracy, reliability, and traceability of measurement instruments used in geotechnical, structural, and construction applications. Proper calibration enables precise quantification of measurement uncertainties and establishes the sensitivity of electronic signals to the applied measurand. At Geonamics, we provide comprehensive calibration services to maintain the performance and accuracy of critical instrumentation. Our state-of-the-art calibration facilities ensure that instruments are tested under controlled conditions with reference to traceable standards, allowing engineers to have full confidence in their measurements. The following calibration services are available:

Strain Transducer Calibration

Accelerometer Calibration

Accelerometers used in High Strain Dynamic Load Testing (HSDLT) play a crucial role in measuring acceleration upon dynamic impact, which is fundamental to deduce pile velocity response and the pile top displacement. With this measurement, the pile capacity can be estimated. The Accelerometer Calibration process involves subjecting the device to controlled vibratory motion at various frequencies and amplitudes while measuring the electrical output response. This calibration determines the sensitivity of the accelerometer, ensuring that its readings accurately represent pile motion characteristics during HSDLT. At Geonamics, we provide traceable and high-accuracy Accelerometer Calibration, ensuring consistent and precise HSDLT results.

Hydraulic Jack Calibration

Hydraulic jacks are extensively used in the prestressing industry, particularly in post-tensioning and pre-tensioning applications where precise force application is critical for structural integrity. Over time, hydraulic systems may experience pressure deviations, leading to inaccurate force measurements, which can compromise safety and performance. The Hydraulic Jack Calibration process involves applying controlled loads while monitoring the pressure-force relationship, ensuring that the hydraulic system delivers accurate and consistent force output. Calibration helps in quantifying uncertainties and validating the accuracy of applied loads, ensuring compliance with industry standards for force measurement in prestressing applications. Geonamics provides Hydraulic Jack Calibration using high-precision load reference systems, ensuring traceable and accurate force measurement for prestressing operations in bridge and structural construction.